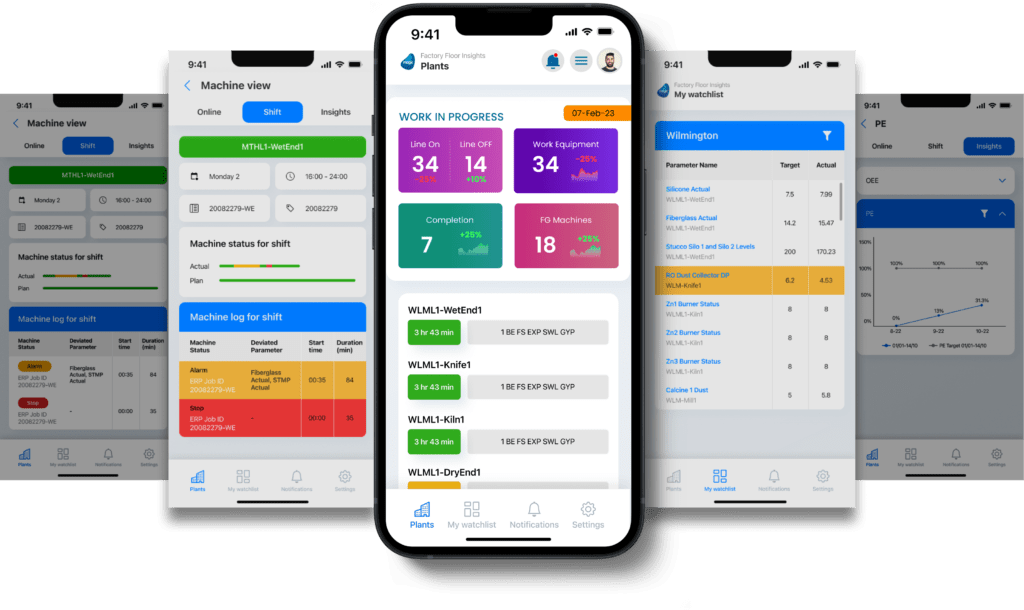

Transforming Factory Operations with Industrial IoT Mobile Application for Magic software.

Customer

With over 30 years of experience, Magic Software has established its position in the market as a global software provider, present in 24 regional offices, with millions of installations worldwide, and strategic alliances with global IT leaders, such as IBM, Microsoft, Oracle, Salesforce.com, and SAP.

Magic Software provides an Industrial IoT Mobile application platform to help a leading industrial company specializing in automotive components, seeks to optimize factory operations and gain real-time insights into their production processes.

- Data Silos: XYZ Manufacturing faces challenges in aggregating data from disparate systems and equipment across the factory floor, limiting their ability to gain comprehensive insights.

- Limited Visibility: Without real-time monitoring capabilities, the company struggles to identify inefficiencies and bottlenecks in their production processes.

- Complexity of Implementation: Integrating IoT sensors and devices into existing machinery and infrastructure poses technical challenges and requires expertise in both hardware and software integration.

- User Adoption: Convincing factory floor workers to embrace new technologies and processes can be challenging, as they may resist changes that disrupt their established workflows.

- Data Security: Protecting sensitive manufacturing data from cyber threats and ensuring compliance with industry regulations are critical concerns for XYZ Manufacturing

To address these challenges, XYZ Manufacturing proposes the development of an Industrial IoT mobile application with the following features:

- Intuitive UX-UI Design: Designing a user-friendly interface that simplifies data visualization and interaction, making it easy for factory floor workers to access and interpret real-time insights.

- Real-time Monitoring: Implementing features that provide instant access to critical operational data, allowing managers and supervisors to make informed decisions quickly.

- IoT Device Integration: Streamlining the integration of IoT sensors and devices into existing machinery and infrastructure, ensuring seamless data collection and transmission.

- Training and Support: Providing comprehensive training and ongoing support to factory floor workers to facilitate smooth adoption of the mobile application and IoT technology.

- Data Encryption and Compliance: Implementing robust data encryption measures and ensuring compliance with industry regulations to protect sensitive manufacturing data.

- Scalability and Flexibility: Building a scalable and flexible application architecture that can accommodate the evolving needs of XYZ Manufacturing’s factory operations and support future growth.

Following the implementation of the Industrial IoT mobile application, XYZ Manufacturing experienced the following outcomes:

- Improved Operational Efficiency: The intuitive UX-UI design of the application made it easier for factory floor workers to access and understand real-time insights, leading to streamlined operations and increased productivity.

- Enhanced Decision-making: Real-time monitoring capabilities empowered managers and supervisors to make informed decisions quickly, enabling them to respond promptly to production challenges and optimize processes for efficiency.

- Increased Worker Engagement: Through comprehensive training and support, factory floor workers embraced the new technology, recognizing its potential to improve their work environment and performance.

- Enhanced Data Security: Robust data encryption measures and compliance with industry regulations ensured the security and integrity of manufacturing data, mitigating the risk of cyber threats and data breaches.

- Scalability and Adaptability: The scalable and flexible application architecture allowed for seamless integration of additional IoT devices and features as manufacturing operations evolved, ensuring continued relevance and effectiveness.

Overall, the Industrial IoT mobile application transformed the Manufacturing’s factory operations, enabling them to gain valuable insights, optimize processes, and stay competitive in the ever-evolving industrial landscape.

- UX-UI

- Figma

- Native Android

- Swift

- Data Silos: The Manufacturing company faced challenges in aggregating data from disparate systems and equipment across the factory floor, limiting their ability to gain comprehensive insights.

- Limited Visibility: Without real-time monitoring capabilities, the company struggles to identify inefficiencies and bottlenecks in their production processes.

- Complexity of Implementation: Integrating IoT sensors and devices into existing machinery and infrastructure poses technical challenges and requires expertise in both hardware and software integration.

- User Adoption: Convincing factory floor workers to embrace new technologies and processes can be challenging, as they may resist changes that disrupt their established workflows.

- Data Security: Protecting sensitive manufacturing data from cyber threats and ensuring compliance with industry regulations are critical concerns for the company.

To address these challenges, the manufacturing company proposed the development of an Industrial IoT mobile application with the following features:

- Intuitive UX-UI Design: Designing a user-friendly interface that simplifies data visualization and interaction, making it easy for factory floor workers to access and interpret real-time insights.

- Real-time Monitoring: Implementing features that provide instant access to critical operational data, allowing managers and supervisors to make informed decisions quickly.

- IoT Device Integration: Streamlining the integration of IoT sensors and devices into existing machinery and infrastructure, ensuring seamless data collection and transmission.

- Training and Support: Providing comprehensive training and ongoing support to factory floor workers to facilitate smooth adoption of the mobile application and IoT technology.

- Data Encryption and Compliance: Implementing robust data encryption measures and ensuring compliance with industry regulations to protect sensitive manufacturing data.

- Scalability and Flexibility: Building a scalable and flexible application architecture that can accommodate the evolving needs of factory’s operations and support future growth.

Following the implementation of the Industrial IoT mobile application, the customer experienced the following outcomes:

- Improved Operational Efficiency: The intuitive UX-UI design of the application made it easier for factory floor workers to access and understand real-time insights, leading to streamlined operations and increased productivity.

- Enhanced Decision-making: Real-time monitoring capabilities empowered managers and supervisors to make informed decisions quickly, enabling them to respond promptly to production challenges and optimize processes for efficiency.

- Increased Worker Engagement: Through comprehensive training and support, factory floor workers embraced the new technology, recognizing its potential to improve their work environment and performance.

- Enhanced Data Security: Robust data encryption measures and compliance with industry regulations ensured the security and integrity of manufacturing data, mitigating the risk of cyber threats and data breaches.

- Scalability and Adaptability: The scalable and flexible application architecture allowed for seamless integration of additional IoT devices and features as manufacturing operations evolved, ensuring continued relevance and effectiveness.

Overall, the Industrial IoT mobile application transformed the Manufacturing’s factory operations, enabling them to gain valuable insights, optimize processes, and stay competitive in the ever-evolving industrial landscape.

- UX-UI

- Figma

- Native Android

- Swift

- 2 - Online marketplace for agricultural products

- 4 - Obstetrics & Gynaecology mobile app